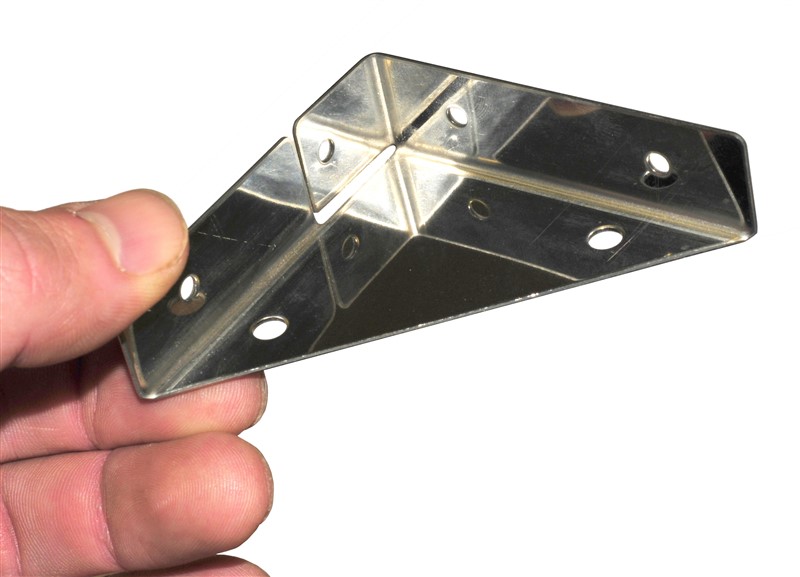

Sheet Metal Presswork

What is Sheet Metal Presswork and what is a power press?

A power press is simply a machine that uses mechanical or hydraulic power to move a ram up and down or in and out. The ram is attached to a tool that can built to perform a simple operation or a series of them. These operations can include cutting, punching, forming and folding. The tools are commonly referred to as press tools or stamping tools.

The tools can operate with a cut to size material blank or coil strips using feeders and de-coiling machines. Press tools can form part of a production item or in some instances produce the complete components in one pass. For instance a single tool may firstly make a square bank into a circle. Then, a second tool may make that circle into a bowl. However, a progression tool may take a material strip and use the tool to make numerous hits, without switching tools.

We have six power press machines which allow us to offer sheet metal presswork up to 150 tons. Our presses include machines by SMV, HME, Butterley, Sweeney & Blocksidge and Hare.

Designed in house to match the application, each sheet metal press work project requires dedicated tooling. If you don’t already have tooling then we can discuss this with you before the design tooling process. If you do have tooling then we may be able to utilise that and offer our services for the production part of the process.

See our equipment page for more details.